Why are the numbers on the board builder different than the one on the board's website description? And, why is the final product different from both of the other numbers?

To be honest, we have literally, thousands of skews. Sometimes the numbers need to be updated. Over time designs change slightly. Especially the volume numbers. If you get a certain volume on the board builder, please realize that I am the one that designed the board in the first place.

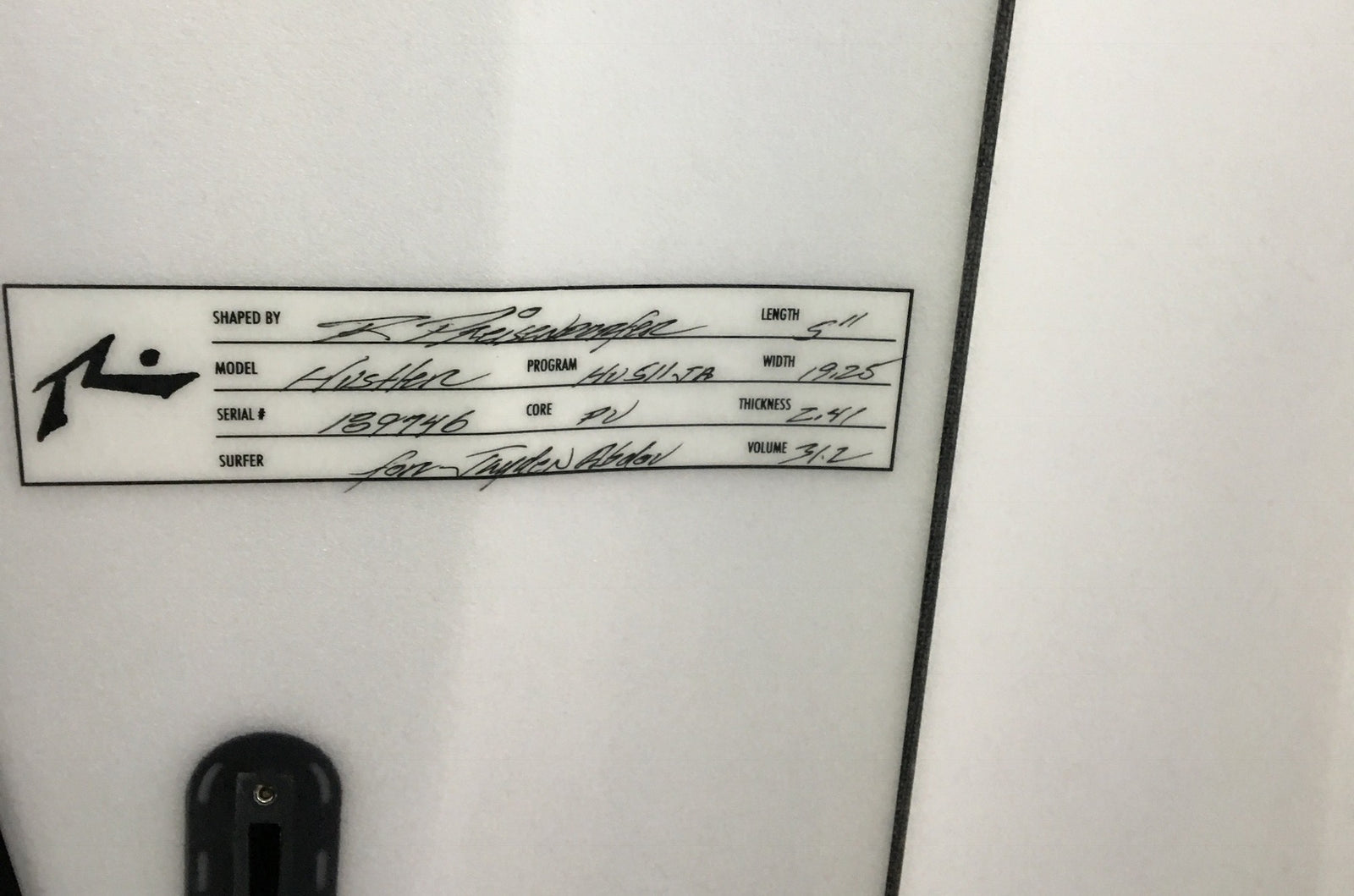

I can hit a different volume number if it’s within a few tenths of a liter. Anything more, the thickness will have to change. Or the rails. The greater the difference, the more the true design gets distorted. You need to specify volume or weight, which is more important to you. Sometimes the numbers may end up being a compromise.

There is no real simple numeric way to measure the volume change in the rails.With everything else being the same, the volume can change in the rails. 1 to 3 liters depending on the size of the board. There is no real simple numeric way to measure the volume change in the rails. Words like leaner, thicker, fuller, angular, less on top, etc. are what surfers use. Rails are very complicated. It’s best if you trust your shaper.

Other numbers; I sometimes round the width or thickness up or down a bit to get the final product closer to what I believe is right for you. For example; 6’0 18.89 2.31 vol 27.21. I could round it off to 18.9, 2.3, 27.2. You are not going to feel a few hundredths of an inch. For that matter, a tenth of an inch. That’s less than an 1/8 of an inch.

The machine doesn’t cut perfectly every time. Fact; there is approximately a 5% variance. As there is with the finish sanding. Body weight varies 3.5% give or take throughout the day. On a short board, worrying about a half a liter is worrying about less than 1.5%.

What about the weight of your surfboard? Yes, a board can be too heavy, or too light. 6.5 lbs? 6.0 lbs? That’s roughly a 10% difference. That’s something that very few customers even question.

I use a formula when I build a model.I use a formula when I build a model. I scale the board up or down in size using the formula. That provides a fairly consistent change in width, thickness, and volume. Are these the optimum numbers? Not necessarily. They are a guide.

There are many other things to also consider such as; deck contour…flat, light crown, or very domed deck, width, rocker, bottom contours, and thickness flow, rail shape, where the apex is placed, fin position, cant, angle to the nose, fin templates, fin construction, glassing schedule, type of cloth used, and weight of the finished board.

You should trust your shaper.